| Raw Material | 50D–1000D Polyester, Polyamide, and so on |

| Sections | ≤10 |

| Twisting Range | 160−2400 T/M |

| Twister Direction | S or Z |

| Take-up Speed | ≤100 m/min |

| Rated Power | 21.4 KW |

| Take-up Bobbin Size | The Bobbin with edge, L230,290 mm |

| Reversing Bobbin | OD42 X ID38, L350−270 mm |

| Tensioner | Ball, Capsule Tension Device |

| Start Model | Y-Δ Slowly Start |

| Type | Double Sides Single Layer, Thread Manually |

| Spindle Driving Mode | Belt Circulatory Driving |

| Take-up Package | 2−5 kg |

| Spindle Distance | 400 mm |

| Setting Spindle Qty/Section | 10 |

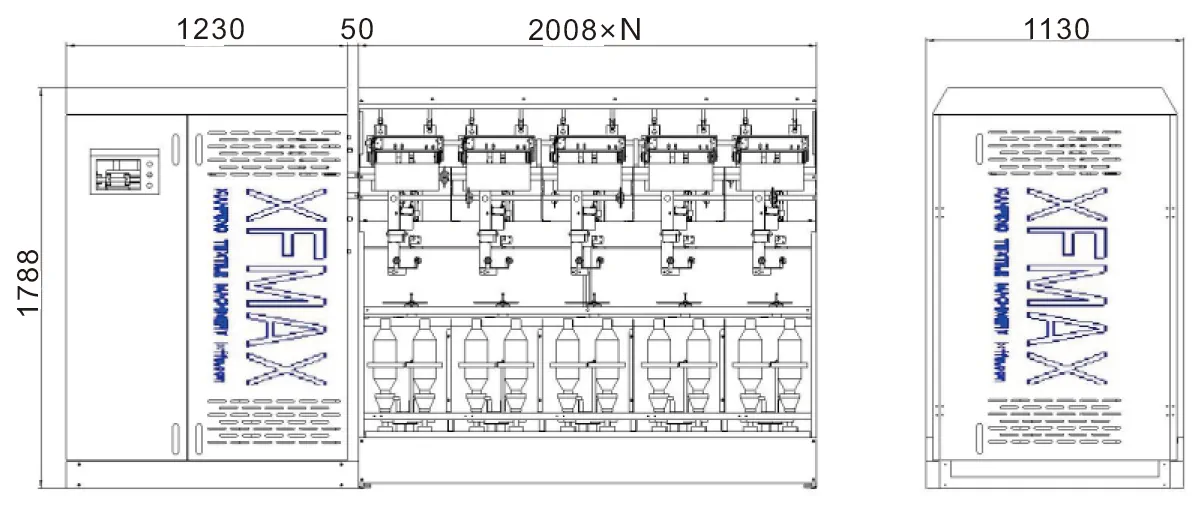

| Size – 10 sections (LxWxH mm) | 21360×1130×1788 |

| Spindle Speed (RPM) | 5000−10000 |

We use cookies on our website to provide you with a better experience.

Your personal data is processed in accordance with our privacy policy under the scope of the KVKK (Law on the Protection of Personal Data). By continuing to use our site, you agree to the use of cookies.

For detailed information, please review our KVKK Disclosure Text and Cookie Policy pages.

Gizlilik ve Çerez Kullanımı

Web sitemizde size daha iyi bir deneyim sunmak için çerezler kullanıyoruz. Kişisel verileriniz, KVKK kapsamında gizlilik politikamıza uygun şekilde işlenmektedir. Sitemizi kullanmaya devam ederek çerez kullanımını kabul etmiş olursunuz. Detaylı bilgi için KVKK Aydınlatma Metni ve Çerez Politikası sayfalarımızı inceleyebilirsiniz.