Yarn Winding Machines

Yarn Winding Machines

Our Yarn Winding Machines, which provide high-speed and precise transfer, optimize your production processes with their advantages of energy efficiency and long-lasting use. Their durable structure and modern design guarantee continuity in textile production.

Bobbin Transfer Winding Machines

Designed to suit various bobbin sizes, our Bobbin Transfer Winding Machines offer a perfect fit for your production line with their durable and ergonomic structure. They provide reliable performance for many years with minimum maintenance needs, thereby lowering operating costs.

Yarn Reel Winder Machines

Our Yarn Reel Winder Machines, equipped with precise transfer technology, provide ease in production with user-friendly control systems. They offer uninterrupted production support, delivering high efficiency and quality standards simultaneously.

Yarn Winding Machines General Features

General Capacity and Flexibility:

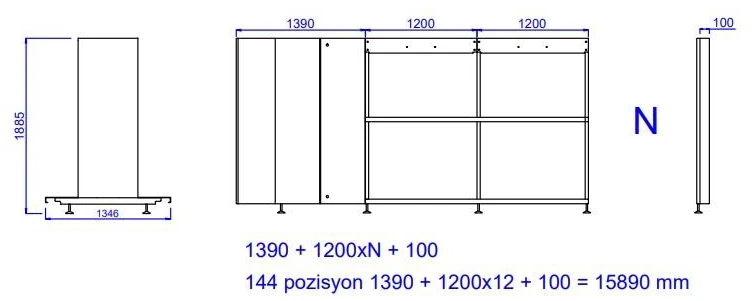

- Wide Production Range: The machine can be produced modularly from 12 positions up to 144 positions. This adapts to your production needs of every scale.

Motor and Drive System:

- High-Efficiency Main Motor: Reliable and powerful energy transfer with 2.2 kW or 5.5 kW asynchronous main motor options, depending on the requirement.

- Precise Traverse Control: 0.37 kW or 0.75 kW servo motor-driven Traverse System ensuring yarn smoothness and excellent bobbin quality.

- Automation and Control: Reliable Electronic Infrastructure: All PLC, Screen, and Inverter components are DELTA brand. It offers proven industrial quality control and performance.

- Touch Screen Control: All operating settings are managed via an easy-to-use touch screen. Ensures quick setup and minimum operator error.

- 99 Program Memory: Save frequently used winding settings for fast changeovers.

- Flexible Winding Types: Supports 4 different cops winding, reel, and bottle (cone) winding types. Respond to different customer demands with a single machine.

Durability and Structure Superior Chassis Durability (Laser Cut):

- All parts of the machine are produced with laser cutting precision. This ensures perfect assembly and long-lasting use.

- Robust Construction Thicknesses:

- Legs: 5 mm

- Spindle Plates / Head Plates: 4 mm (Solid structure with high vibration resistance)

- Bottom and Top Bobbin Plates: 3 mm

- Spindle Covers: 2 mm

Dimensions

For 108 positions: 12290×1346×1885 mm (LxWxH)